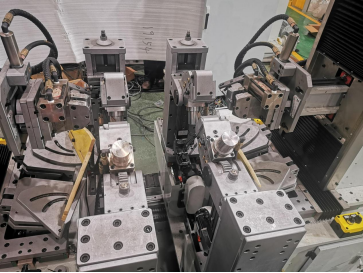

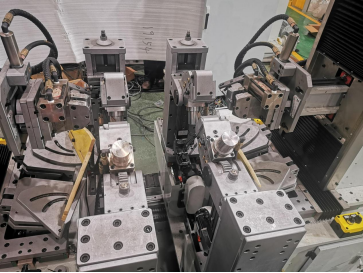

Equipment performance:

1.The equipment control system’s human-machine interface inputs the coil forming parameters, programs through the PLC, after manually installing the winded coil, start the button, then the equipment can automatically control the automatic running of the nose clamp, the straight part clamp, the forming arm and the bevel edge’s forming position, the equipment can automatically complete the circle coil’s straight part length & angle, the end top arc and the nose height’s automatic operation process according to the procedures in order.

2.After the coil forming, the fixture automatically loosen, manually remove the coil, the equipment state automatically resets.

3.CNC servo motor is used to control the pulling of the coil span and angle, adjust on the touch screen. It has very easy solution method to the coil’s rebound problem.

4.Equipment has the function of automatic distance and centering to make sure the coils meet the design requirements.

5.Equipment's end top arc system adopts the multi-board joining type, join out different arc to ensure the end forming requirements of the different specification coils.

6.Equipment’s clamp can adjust 0-150°, the linear edge and the end corner won't bulge or concave, the clamp locks and won’t move in the forming process to ensure no abrasion between coils.

7.With the fault alarm prompt system and the necessary protection stop function.

Copyright 2023 All Rights Reserved. 地址:No.5 Building, 1068 Xinmiaosan Road, Xinqiao Town, Songjiang District, Shanghai, China 苏ICP123456 XML地图 网站模板